Modernizing Smart Warehouse Operations With InnoAioT 10"Industrial Computers

Time:2025-07-23 10:08:00

Visit:188

Global logistics and warehouse management systems are undergoing a technological revolution, driven by the rise of e-commerce, demand for faster order fulfillment, and the need for more efficient inventory management. According to recent reports, the global warehouse automation market is projected to grow at a CAGR of 14.3% from 2023 to 2028, fueled by technological advancements such as the Internet of Things (IoT), Artificial Intelligence (AI), and robotics.

Smart warehousing refers to the integration of cutting-edge technologies to optimize the storage, inventory management, and order fulfillment processes in warehouses. Unlike traditional warehouses, which rely heavily on manual labor and static workflows, smart warehouses leverage automation, real-time monitoring, and data analytics to increase operational efficiency and reduce costs.

For years, warehouses have functioned as traditional storage facilities, relying on human labor, paper-based tracking systems, and forklifts to handle goods. However, as labor costs rise, space becomes more constrained, and the need for real-time tracking intensifies, traditional methods are becoming increasingly inefficient.

Smart warehouses rely on technology to provide real-time visibility, automation, and intelligent decision-making. One of the key enablers of this transformation is the 10" Industrial Panel PC, a rugged and versatile computing solution designed to optimize operations in challenging industrial environments.

Smart warehousing relies on advanced technologies that enable real-time data processing, automation, and predictive analytics. These technologies include:

As warehouses become more automated, integrating industrial computing solutions like the 10" Industrial Panel PC with IoT is essential for real-time monitoring and decision-making. These devices help ensure that warehouse operations run smoothly, safely, and efficiently.

InnoAioT’s 10" Industrial Panel PCs are designed to elevate warehouse operations by offering rugged durability, powerful performance, and seamless integration with IoT and AI technologies. With a range of customizable options, these devices are suited for various warehouse environments, including automated systems, material handling, and fleet management.

As the warehouse industry continues to evolve, the integration of automation, AI, and IoT will drive further advancements in operations. 10" Industrial Panel PCs will play a central role in this transformation, providing the computing power necessary for real-time data processing, fleet optimization, and automated decision-making.

Ready to optimize your warehouse operations? Discover how InnoAioT’s 10" Industrial Panel PC can help you achieve greater efficiency, accuracy, and flexibility in your logistics operations.

For more information about InnoAioT’s 10" Industrial Panel PC, please visit our website or contact us at info@innoaiot.com.

Smart warehousing refers to the integration of cutting-edge technologies to optimize the storage, inventory management, and order fulfillment processes in warehouses. Unlike traditional warehouses, which rely heavily on manual labor and static workflows, smart warehouses leverage automation, real-time monitoring, and data analytics to increase operational efficiency and reduce costs.

The Shift Toward Smart Warehousing

For years, warehouses have functioned as traditional storage facilities, relying on human labor, paper-based tracking systems, and forklifts to handle goods. However, as labor costs rise, space becomes more constrained, and the need for real-time tracking intensifies, traditional methods are becoming increasingly inefficient.

The challenges faced by traditional warehouses include:

- • High labor costs due to manual processes.

- • Inventory inaccuracies that lead to stockouts and delays in fulfillment.

- • Poor space utilization that leads to wasted storage.

- • Lack of real-time visibility making demand forecasting difficult.

How 10" Industrial Panel PCs Enhance Smart Warehousing

Smart warehouses rely on technology to provide real-time visibility, automation, and intelligent decision-making. One of the key enablers of this transformation is the 10" Industrial Panel PC, a rugged and versatile computing solution designed to optimize operations in challenging industrial environments.

Key Features of 10" Industrial Panel PCs in Smart Warehousing:

- • Compact and Durable Design: These devices are built to withstand the demanding conditions of warehouses, including high vibration, dust, and temperature extremes. The IP65-rated design ensures protection against dust and water, making them ideal for harsh warehouse environments.

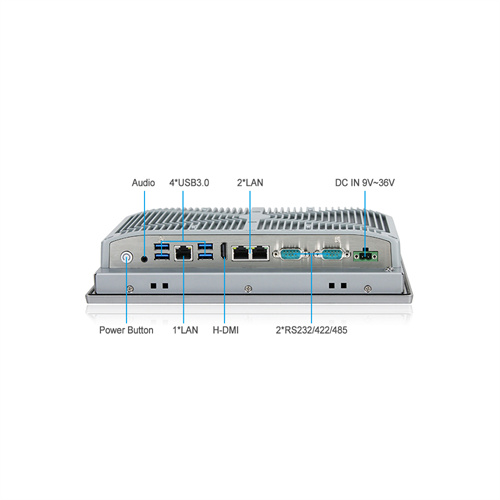

- • Enhanced Connectivity: With support for Wi-Fi, Bluetooth, 4G/5G, and GPS, 10" industrial panel PCs ensure seamless communication between devices, warehouse management systems (WMS), and Automated Guided Vehicles (AGVs), enabling real-time decision-making.

- • Touchscreen Interface: The PCAP touchscreen offers an intuitive, user-friendly interface that allows warehouse staff to easily interact with warehouse management systems (WMS), scan barcodes, and monitor inventory levels.

- • High-Performance Processing: Powered by robust processors, these industrial panel PCs handle demanding tasks such as predictive analytics, automated order fulfillment, and real-time data collection without performance degradation.

- • Flexible Mounting: With multiple mounting options, the 10" industrial panel PC can be installed on forklifts, trucks, and AGVs, providing continuous access to operational data across the warehouse.

The Core Technologies Behind Smart Warehousing

Smart warehousing relies on advanced technologies that enable real-time data processing, automation, and predictive analytics. These technologies include:

- • Internet of Things (IoT): The integration of IoT-enabled devices such as RFID scanners, sensors, and smart cameras provides real-time inventory tracking and automated material handling, improving operational efficiency.

- • Artificial Intelligence (AI): AI-driven decision-making helps optimize inventory levels, predict demand, and automate order fulfillment, reducing the chance of human error and delays.

- • Edge Computing: By processing data locally on devices like the 10" Industrial Panel PC, edge computing ensures faster decision-making and real-time tracking, even in areas with limited network connectivity.

- • 5G Connectivity: 5G-enabled devices enhance real-time communication, providing instant updates and seamless integration across the entire warehouse operation.

Integrating 10" Industrial Panel PCs with IoT for Smarter Operations

As warehouses become more automated, integrating industrial computing solutions like the 10" Industrial Panel PC with IoT is essential for real-time monitoring and decision-making. These devices help ensure that warehouse operations run smoothly, safely, and efficiently.

- • Inventory Management: With built-in barcode scanners and RFID integration, 10" Industrial Panel PCs help track inventory levels in real-time, ensuring accurate stock counts and reducing stockouts.

- • Fleet Management: These devices integrate seamlessly with AGVs and forklifts, enabling automated route optimization, fleet tracking, and efficient material transport.

- • Predictive Maintenance: By integrating sensors and monitoring equipment health, the 10" Industrial Panel PC can alert operators to potential equipment failures, enabling proactive maintenance and reducing downtime.

- • Enhanced Worker Safety: With real-time alerts, temperature, and humidity monitoring, and remote diagnostics, these devices ensure that warehouse operations adhere to safety standards and regulations.

InnoAioT’s 10" Industrial Panel PC: Optimizing Warehouse Automation

InnoAioT’s 10" Industrial Panel PCs are designed to elevate warehouse operations by offering rugged durability, powerful performance, and seamless integration with IoT and AI technologies. With a range of customizable options, these devices are suited for various warehouse environments, including automated systems, material handling, and fleet management.

Key Advantages of InnoAioT’s 10" Industrial Panel PC for Smart Warehousing:

- • Compact Design: Available in 10" screen size, ideal for tight spaces and mobile applications such as forklifts and AGVs.

- • Rugged Construction: IP65-rated for dust and water resistance, ensuring long-lasting durability in industrial environments.

- • Powerful Performance: Equipped with advanced processors and ample memory, enabling efficient handling of data and real-time communication.

- • Seamless Integration: Supports various I/O ports and connectivity options like Wi-Fi, Bluetooth, and 4G/5G, making it easy to integrate with existing warehouse systems.

- • Cross-Platform Compatibility: Supports Windows, and Linux operating systems, ensuring compatibility with a wide range of warehouse management systems.

The Future of Smart Warehousing:

As the warehouse industry continues to evolve, the integration of automation, AI, and IoT will drive further advancements in operations. 10" Industrial Panel PCs will play a central role in this transformation, providing the computing power necessary for real-time data processing, fleet optimization, and automated decision-making.

Ready to optimize your warehouse operations? Discover how InnoAioT’s 10" Industrial Panel PC can help you achieve greater efficiency, accuracy, and flexibility in your logistics operations.

For more information about InnoAioT’s 10" Industrial Panel PC, please visit our website or contact us at info@innoaiot.com.