Empowering AGV Mobile Robots with InnoAioT EFIC-1000 Industrial Computers

The Company

- • A leading solution provider in the field of AGV (Automated Guided Vehicle) mobile robots, integrating advanced computer control systems, electronic control equipment, and automatic guidance technologies such as electromagnetic and optical navigation.

- • Specializes in intelligent industrial control hardware and system-level solutions that support autonomous movement, multi-sensor control, network interaction, and intelligent decision-making.

- • Committed to delivering end-to-end automation solutions that improve warehouse logistics, order picking, material handling, and transportation efficiency.

- • With strong expertise in lidar, depth cameras, and sensor integration, their AGV robots help customers achieve safe identification, automatic obstacle avoidance, precise sorting, and efficient handling.

- • The company serves industries such as warehousing, logistics, e-commerce, manufacturing, and emerging technology sectors, addressing the growing need for automation amid labor shortages and rising operational demands.

The Challenges

- • Increasingly complex warehousing requirements demand high-performance computing to process massive amounts of data, including mapping tens of thousands of warehouse locations, tracking order numbers, and monitoring pallet movements.

- • AGVs rely on multiple sensors such as front-mounted object detection cameras and positioning cameras, which require embedded computers with rich I/O interfaces to connect cameras, motors, and wireless networks.

- • Power consumption is a critical issue — AGVs require frequent charging, and excessive power use reduces available working time, impacting overall productivity and operational efficiency.

- • The main control computer must ensure stability and reliability for 24/7 continuous operation under harsh warehouse and logistics environments, with resistance to dust, vibration, and temperature fluctuations.

- • Traditional embedded solutions often fail to meet the low-power, high-stability, and rugged design requirements for large-scale AGV deployments.

The Solution

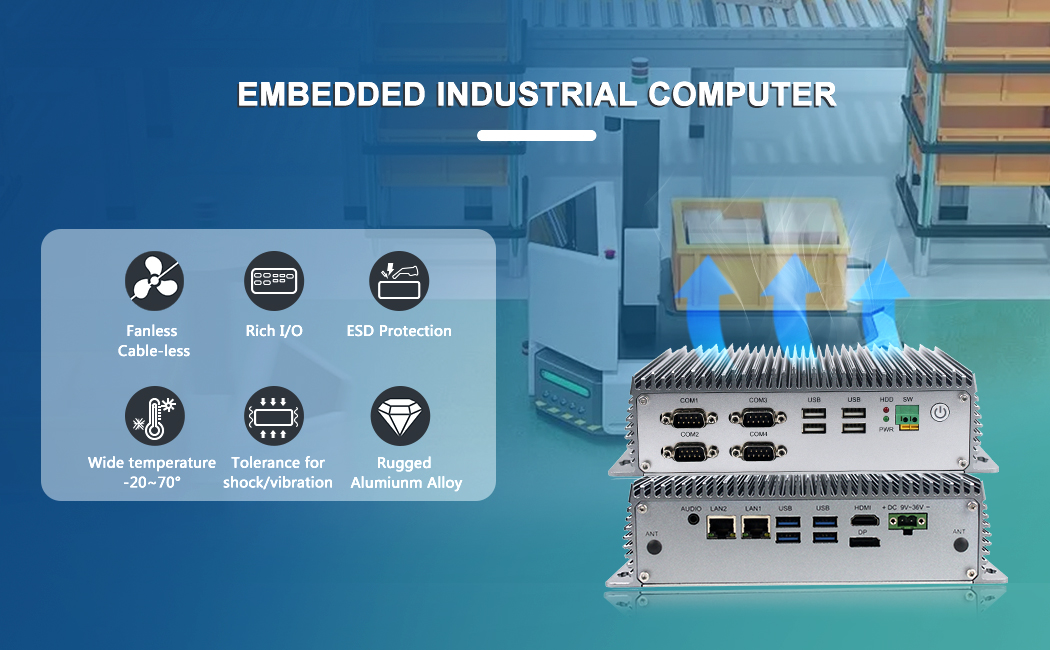

InnoAioT EFIC-1000 Series Embedded Industrial Computer was selected as the core computing platform for AGV mobile robots, designed to provide high-performance computing while maintaining low power consumption and industrial-grade reliability.

Intel 8th Gen Core Platform for High Performance

Powered by Intel 8th Gen Core i3/i5/i7 U-series processors, the EFIC-1000 series delivers the necessary processing power to handle intensive AGV tasks such as mapping, object detection, and real-time navigation. It supports up to 32GB DDR4 memory and multiple storage options (SATA and M.2), ensuring smooth data processing and storage capabilities for large-scale operations.

Rich Connectivity for AGV Applications

The EFIC-1000 comes with 4 Gigabit Ethernet ports supporting Wake-on-LAN and PXE boot, ensuring stable and high-speed data communication with cameras, lidar, and central control rooms. In addition, it offers COM, USB, GPIO, and CAN I/O options, providing flexible connectivity for AGV sensors and actuators. Wireless communication is supported via Wi-Fi, 3G, 4G, ensuring seamless network interaction across the warehouse.

Rugged, Fanless, and Energy-Efficient Design

The EFIC-1000 series adopts a fanless all-aluminum alloy structure, providing excellent shock resistance, dustproofing, high-temperature resistance, and electromagnetic compatibility. With wide-voltage DC 9–36V power input and low-power CPU design, it maximizes AGV battery efficiency and ensures stable operation even under fluctuating power conditions.

Advanced Security and Reliability

To further enhance system integrity, the EFIC-1000 supports TPM 2.0 encryption modules, strengthening cybersecurity in connected AGV operations. Built in strict accordance with industrial standards, the system is capable of 24/7 continuous operation in demanding environments.

The Result

- • Enhanced processing performance enabled AGVs to handle large-scale data-intensive tasks, ensuring accurate mapping, object detection, and real-time order tracking.

- • Extended battery life and uptime thanks to low-power design, maximizing AGV availability between charging cycles and improving overall productivity.

- • Strong environmental adaptability and rugged design guaranteed 24/7 stable operation, even in dusty, vibration-prone, and temperature-fluctuating warehouse environments.

- • Improved system integration and flexibility with rich I/O and connectivity options, supporting future scalability and customization for AGV deployments.

- • Greater security and reliability through TPM 2.0 and industrial compliance, ensuring safe and trusted operations across logistics and warehousing sectors.

Background

AGV mobile robots are transforming the logistics and transportation industry, particularly as demographic shifts reduce labor availability and accelerate automation adoption. By integrating sensors such as lidar and depth cameras, AGVs deliver autonomous navigation, obstacle avoidance, intelligent decision-making, and real-time execution.

These capabilities enable efficient handling and precise sorting without direct human supervision, improving work efficiency and quality. With the expansion of automation upgrades and applications in emerging fields, AGV robots are rapidly scaling across industries, showing strong market development potential.

The Challenge

Despite the promise of automation, traditional embedded solutions fall short of meeting the demanding computing and environmental requirements of AGV systems.

- • Intensive computing is required for multi-sensor fusion, real-time navigation, and warehouse-scale mapping.

- • High power consumption reduces AGV availability, creating bottlenecks in productivity.

- • Industrial deployment requires rugged durability, fanless cooling, wide power input, and continuous 24/7 reliability, which standard PCs cannot deliver.

As a result, the solution provider needed an embedded industrial computer that could seamlessly integrate with AGV systems, support high-performance AI-driven operations, and provide low-power, stable, and rugged reliability in logistics environments.

The Solution

The InnoAioT EFIC-1000 Series Embedded Industrial Computer was selected to address these challenges with its Intel 8th Gen Core processors, fanless industrial design, wide power support, and rich I/O interfaces.

It not only ensured powerful computing for sensor integration and navigation but also delivered low power consumption, extending AGV battery uptime. With rugged construction and advanced connectivity, the EFIC-1000 provided the ideal balance of performance, efficiency, and reliability required for AGV operations.

The Benefits

High-Performance with Low Power

The Intel 8th Gen Core i5/i7 U-series processors deliver strong processing performance with energy-efficient operation, maximizing AGV productivity while minimizing downtime.

Industrial-Grade Reliability

The all-aluminum alloy structure, fanless design, wide-voltage power input, and industrial-grade EMC compliance ensure stable 24/7 operation in harsh logistics environments.

Enhanced Connectivity and Security

With multiple Gigabit LAN ports, flexible I/O, wireless support, and TPM 2.0 encryption, the EFIC-1000 series provides robust connectivity and strong data security for intelligent AGV deployments.

Future Scalability and Flexibility

The modular and rich interface design ensures AGV systems can be easily upgraded and scaled for new application requirements, protecting long-term investment and enabling future innovation.