The Role of Industrial Monitors in Process Control Systems

Various industries, including manufacturing and pharmaceuticals, rely on these monitors. They are customizable to meet specific needs, such as size and resolution. The integration of industrial monitors with automation systems leads to improved efficiency. They are essential for maintaining process consistency and quality control.

Understanding Process Control Systems in the Industrial Environment

Industrial Automation - The Nerve Center of Modern Factories

Industrial monitors often find themselves paired with embedded PCs to form a robust duo capable of tackling the computational needs of modern industrial environments. Box PCs provide the necessary computing power to process the voluminous data generated in industrial settings, while the monitors offer a user-friendly interface for operators to interact with this data. This synergy allows for more sophisticated analysis, control, and automation capabilities, enhancing both the efficiency and effectiveness of process control systems. Such configurations are crucial for industries aiming to leverage the full potential of smart manufacturing practices and IoT integration.

Real-Time Insights at Your Fingertips

Understanding Industrial Monitors: Definition and Key Features

Key features of industrial monitors include:

- • Robust design: Built to resist dust, moisture, and temperature extremes.

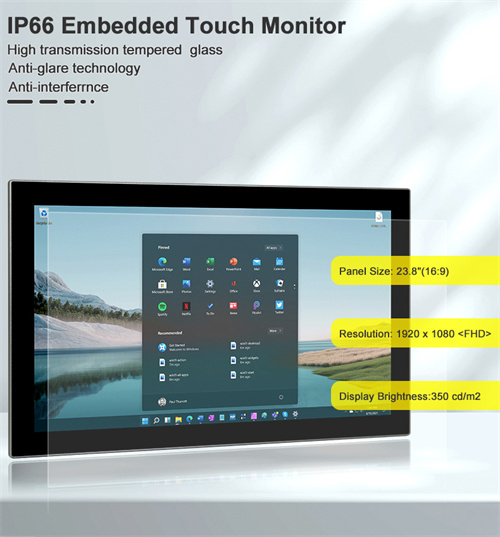

- • Customizable options: Varied sizes, resolutions, and mounting types tailored to industry demands.

- • Advanced connectivity: Support for multiple input/output options for seamless integration.

Moreover, industrial monitors come with touchscreen capabilities. This feature enhances operator interaction through intuitive and easy-to-use interfaces. Their integration with SCADA systems boosts process efficiency. Real-time monitoring and control are pivotal for ensuring safety and regulatory compliance.

Types of Industrial Monitors and Displays

- • Panel mount monitors: Mounted flush with control panels, saving space and enhancing aesthetics.

- • Rack mount monitors: Useful for server racks, providing easy access to data.

- • Open frame monitors: Offer versatility for custom housing options and unique installations.

These monitors also come with various display technologies. LCDs are common, offering clear images and energy efficiency. For outdoor or bright environments, high-brightness displays are available. They ensure visibility in direct sunlight and challenging lighting conditions. Choosing the right type depends on application requirements, space constraints, and environmental factors.

The Importance of Industrial Monitors in Process Control Systems

Key roles include:

- • Enabling data logging for process optimization.

- • Providing visual alerts for immediate issue detection.

- • Supporting remote monitoring for flexible operations.

Industrial monitors enhance system efficiency. They provide operators with user-friendly interfaces and critical insights. By integrating with control systems, monitors ensure smooth operations. Their precise data helps maintain consistent quality.

Industrial Touch Monitors: Enhancing Operator Interaction

Key features of industrial touch monitors:

- • Intuitive touch controls for smooth operation.

- • Anti-glare screens for clear visibility.

- • Quick response times for seamless interaction.

These monitors support real-time adjustments, offering precise control over processes. Their user-friendly design reduces the learning curve for new operators. Touch monitors deliver a hands-on experience that streamlines operations. They align well with modern automation needs, making them a preferred choice for industrial applications.

Applications Across Industries

Key applications across industries include:

- • Monitoring production lines in manufacturing.

- • Supervising drilling operations in oil and gas.

- • Ensuring precision in pharmaceutical processes.

These versatile devices adapt to specific industry requirements. They ensure smooth operations and support compliance with standards. Industrial monitors address unique challenges and optimize processes in different industrial environments.

Key Benefits: Durability, Reliability, and Customization

Customization further extends their capabilities:

- • Tailored sizes to fit specific spaces.

- • Resolution options for clear data display.

- • Diverse mounting configurations for flexible installation.

By reducing downtime and maintenance costs, these monitors improve efficiency. Their resilience and adaptability make them a preferred choice across various industries. Investing in these features ensures enhanced productivity and consistent performance.

Integration with Automation and Control Systems

Key integration benefits include:

- • Enhanced connectivity with control systems.

- • Improved data accuracy and monitoring.

- • Streamlined workflow and reduced human error.

This integration also leads to significant cost savings. Operators gain greater control over processes, resulting in better decision-making and productivity. With these advantages, industrial monitors become indispensable in modern automated environments.

How InnoAioT’s Industrial Monitors Are Shaping the Future of Industry

As a leading provider in industrial computing solutions, InnoAioT recognizes the essential role industrial monitors play in modern process control. Their range of monitors sets the standard in performance and durability, providing solutions designed to meet the evolving demands of industries worldwide.

Tailored Solutions for Every Need

InnoAioT's industrial monitors are designed to be flexible and customizable. Whether you need a compact, rugged display for machinery or a large, high-definition screen for detailed visualizations, InnoAioT offers a variety of options. Customers can select the ideal screen size, resolution, and touchscreen type to suit their specific application needs.

Durability Without Compromise

Built to endure the toughest environments, InnoAioT’s monitors are equipped with industrial-grade components and are sealed to resist the elements. They are shock and vibration-resistant, ensuring consistent and reliable performance even in challenging conditions, where many other monitors might fail.

Forward-Thinking Innovation

InnoAioT’s commitment goes beyond meeting current industry needs; they are also focused on the future. Their ongoing research and development efforts aim to push the boundaries of display technology, ensuring their monitors stay ahead of the curve in industrial computing innovation.

The Heart of Modern Industry Operations

Industrial monitors play an indispensable role in driving the success of modern industrial operations. Though they may not always be in the spotlight, they are critical in promoting efficiency, safety, and regulatory compliance, the key elements of any well-run industrial process.

For engineers and plant managers striving to optimize their operations, industrial monitors are far more than just tools—they are strategic investments that contribute directly to operational excellence. By leveraging the expertise of companies like InnoAioT and keeping up with the latest technological trends, businesses can ensure their process control systems remain at the forefront of the industry. With the right monitors in place, you can manage your operations with greater precision and confidence, confidently navigating the future ahead.