What is a Rugged Embedded PC?

In the world of industrial automation, reliability is key. Systems must endure harsh conditions without faltering. This is where rugged embedded PCs come into play. These specialized computers are designed for tough environments. They thrive in extreme temperatures, dust, and moisture. Their robust nature makes them indispensable in industrial settings.

Rugged embedded PCs are not just about durability. They offer high performance in compact forms. This makes them ideal for integration into existing systems. Their fanless design reduces mechanical failures. This enhances reliability and extends their lifespan. Industrial-grade components ensure they withstand the test of time. These PCs are versatile, supporting various I/O interfaces. This flexibility allows them to meet diverse industrial needs. They are crucial for real-time data processing and control. Security is another strong suit of rugged embedded PCs. They protect against cyber threats, ensuring safe operations. This is vital in today’s interconnected industrial landscape. In essence, rugged embedded PCs are the backbone of modern industrial automation. They ensure efficiency and reliability in challenging environments.

Embedded PCs: The Foundation of Industrial Computing

Embedded computers serve as a crucial component in industrial systems. These compact computers are designed to perform specific tasks efficiently. They are integral to automation processes across various industries. Unlike traditional desktop PCs, embedded PCs are built for particular functions. They control machinery, manage data, and monitor systems. Their design focuses on reliability and functionality over general computing tasks. Embedded PCs come with several advantages. They are energy-efficient, which is vital for prolonged operations. Their small size allows them to fit into tight spaces easily. Here are some key features of embedded PCs:

- • Compact and energy-efficient design

- • Task-specific functionality

- • High reliability and durability

Overall, embedded PCs provide the foundation for modern automation. They connect hardware with software, enabling seamless industrial processes. Their importance in today's industrial landscape cannot be overstated.

What Makes a PC "Rugged"? Key Design Features and Standards

Rugged embedded PCs stand out due to their enhanced durability. They are designed specifically for extreme conditions, ensuring seamless performance in harsh environments. These PCs excel where standard computers might fail. The ruggedness of these PCs comes from their robust construction. High-quality materials and strong enclosures protect them from physical damage. This construction ensures reliability in various challenging settings. Rugged PCs often include fanless designs to mitigate mechanical failures. This feature not only reduces downtime but also extends the system's lifespan, making them a sound investment for critical applications. Temperature extremes are another challenge that rugged PCs are built to face. They typically function within a wide temperature range, often from -30°C to 70°C, ensuring uninterrupted operations. To meet industry standards, rugged embedded PCs are tested extensively. They conform to certifications like IP65/IP67, which ensure resistance against dust and water intrusion. This compliance guarantees their reliability in demanding environments. They also incorporate vibration and shock resistance features. This capability is essential for mobile and transportation sectors, where constant movement is common. Such design elements keep systems operating smoothly even during physical disturbances.

Key design features of rugged embedded PCs include:

- • Fanless construction for increased reliability

- • Extended temperature range for extreme conditions

- • Certification for dust and water resistance

A detailed inspection of these features reveals why these PCs are crucial in industrial settings. Their design caters to environments where consistent, reliable performance is non-negotiable. By understanding these key aspects, industries can better leverage rugged PCs to enhance operations and reduce potential disruptions.

Rugged Embedded PC vs. Standard Embedded PC: A Comparative Analysis

Rugged embedded PCs, however, are built for resilience. They handle extreme temperatures, shocks, and vibrations, making them ideal for demanding locations. Their ability to function in hostile environments ensures operational reliability.

Comparing the two, rugged embedded PCs offer:

- • Enhanced durability

- • Extended temperature range

- • Vibration and shock resistance

For industrial automation engineers, choosing between rugged and standard often depends on the setting. In conditions where durability is paramount, rugged embedded PCs are indispensable. Understanding these comparative aspects helps in selecting the right tool for the task, ensuring the longevity and effectiveness of industrial operations.

Core Components and Architecture of Rugged Embedded PCs

Key components and architecture characteristics include:

- • Robust processing units

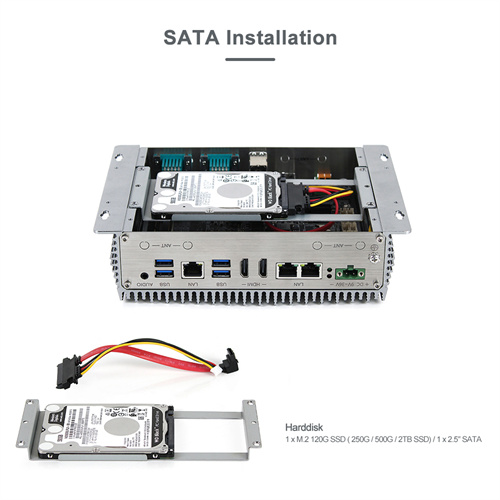

- • Solid-state storage solutions

- • Flexible and customizable I/O interfaces

These elements work in tandem to provide reliable operation. Rugged embedded PCs prove essential for real-time data processing and control, meeting the rigorous demands of industrial applications efficiently.

Environmental Challenges: How Rugged Embedded PCs Withstand Harsh Conditions

Dust and moisture present significant challenges in many industrial contexts. Rugged embedded PCs often comply with IP65 or IP67 standards, offering protection against ingress. This sealing prevents contaminants from compromising the system's functionality. Vibration and shock resistance are also key considerations. Rugged PCs are designed with robust enclosures and shock-absorbing mounts, ensuring stability. The following list highlights essential design features:

- • Wide temperature tolerance

- • Ingress protection (IP65/IP67)

- • Shock and vibration resistance

These design elements equip rugged embedded PCs to weather environmental challenges. Such resilience is crucial for sustaining industrial operations without disruption, reinforcing their value in diverse sectors.

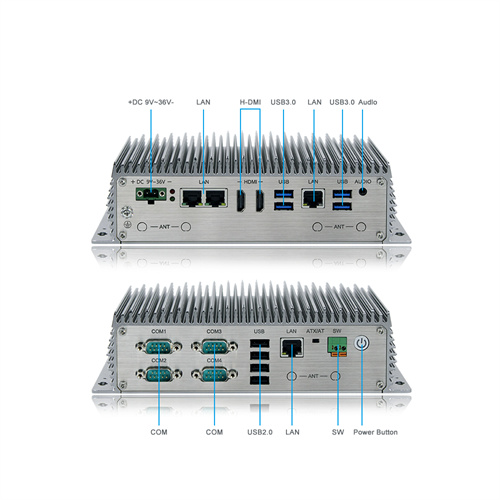

Connectivity and I/O: Meeting the Demands of Industrial Applications

Industrial applications often require diverse connectivity options. Rugged embedded PCs rise to this challenge with versatile I/O interfaces. These interfaces ensure seamless integration into complex industrial networks. A broad array of connectivity options allows them to support multiple communication protocols. Ethernet, CAN bus, and Modbus are commonly supported, ensuring compatibility with existing systems. This flexibility is key in industries with mixed technology environments. The robust I/O capabilities enable interaction with various sensors and devices. USB, serial, and digital input/output ports are typically included. Such interfaces facilitate effective data exchange and machine control.

Here are some common I/O features found in rugged embedded PCs:

- • Multiple Ethernet ports

- • USB and serial interfaces

- • Digital I/O for sensors and actuators

These connectivity features enable rugged embedded PCs to function effectively across different applications. They meet the demands of industrial settings, providing the necessary links to drive automation and efficiency.

Customization and Scalability: Tailoring Solutions for Industrial Needs

Scalability is also a key feature of rugged embedded PCs, allowing seamless expansion. As industrial operations grow, these systems can scale to meet increasing performance and data processing demands. This expansion capability is crucial for industries planning for future growth.

Customization and scalability options often include:

- • Processor types and speeds

- • Memory capacity

- • Storage solutions (e.g., SSDs)

- • Expansion slots for additional modules

These features empower industrial engineers to design computing systems that perfectly fit their unique environments and goals.

Security and Reliability in Rugged Embedded PCs

Security is a top priority in industrial settings, and rugged embedded PCs do not compromise on this front. They incorporate advanced security features to protect against cyber threats, ensuring data integrity and safety. This protection is crucial in maintaining the continuous and secure operation of industrial processes. Reliability is another standout feature of rugged embedded PCs. Their fanless, solid-state designs minimize mechanical failures, making them dependable in demanding conditions. These systems excel in harsh environments, where uninterrupted performance is critical.

Some key security and reliability features include:

- • Advanced encryption protocols

- • Built-in firewalls for network protection

- • Secure boot options to prevent unauthorized access

Together, these features ensure rugged embedded PCs provide a robust foundation for industrial automation. They minimize the risk of downtime and maximize operational efficiency, allowing engineers to focus on optimizing processes and productivity.

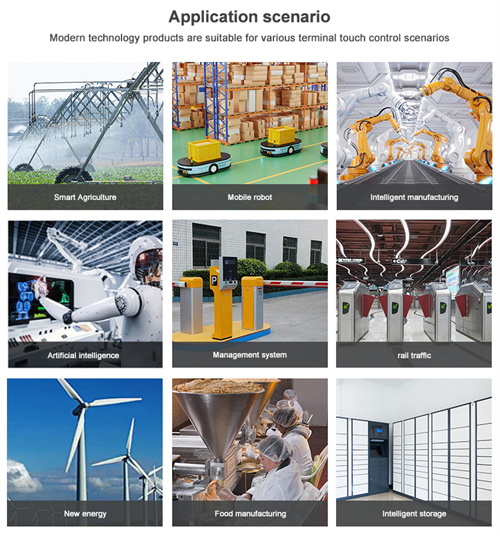

Typical Applications: Where Rugged Embedded PCs Excel

Energy sectors, including oil and gas, also benefit from rugged embedded PCs. These systems perform reliably in hazardous locations, from refining plants to remote drilling sites. Their ability to withstand extreme conditions is vital for maintaining uninterrupted operations. Additionally, rugged embedded PCs support applications in the military and defense. They ensure real-time communication and control in mission-critical scenarios. Their reliability is essential for operations where every second counts.

Key application areas include:

- • Manufacturing automation and control

- • Vehicle telematics and diagnostics

- • Oil and gas exploration

- • Military and defense operations

Selecting the Right Rugged Embedded PC: Key Considerations for Industrial Automation Engineers

Choosing the right rugged embedded PC requires a tailored approach. Industrial automation engineers must consider the specific environmental conditions where the PC will operate. This includes factors like temperature extremes, dust, and vibration levels. Performance requirements are crucial. Engineers should assess the computational demands of their applications. A PC with adequate processing power, memory, and storage ensures smooth operations. Balancing performance with power efficiency is essential for optimal results. Connectivity options are another consideration. Different industrial applications require diverse I/O interfaces and communication protocols. It's important to select a PC offering flexibility in these areas to integrate seamlessly with existing systems. Reliability and lifespan are paramount. Rugged embedded PCs should minimize downtime and be capable of long-term operation. Maintenance and scalability should also be evaluated to ensure future readiness.

Key considerations include:

• Performance and power efficiency

• Connectivity and compatibility

• Reliability and maintenance needs

Where To Get The Best Rugged Embedded PCs For My Industrial Applications?

Trying to find the right rugged computers for your industrial needs can be tough. At InnoAioT, our expert engineers have more than 16 years of experience designing and building reliable computing solutions for businesses. We're here to help you select the best computer for your specific and demanding applications. Contact us today if you need a rugged computer.