How Stainless Steel Pressure Valves Protect Industrial Touchscreen Computers

Introduction

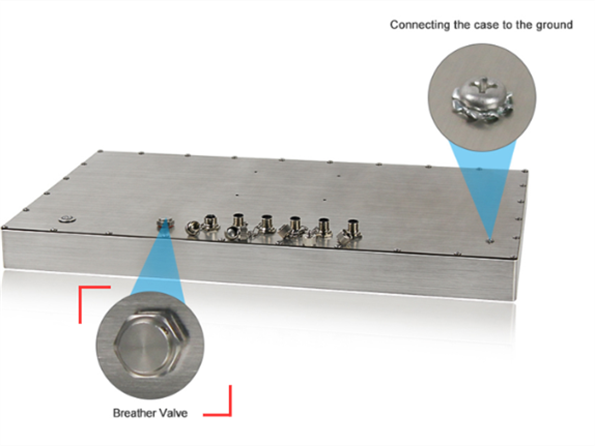

In today’s increasingly automated industrial environments—from food processing and pharmaceutical manufacturing to oil & gas and smart factories—industrial touchscreen computers play a crucial role in real-time control, monitoring, and data management. However, these high-performance devices are often deployed in harsh, contaminant-prone environments, where they face constant threats from dust, moisture, high-pressure washdowns, chemical exposure, and temperature fluctuations.While robust stainless steel enclosures and high IP66/IP69K ratings are commonly seen as the first line of defense, a lesser-known but equally critical component is often overlooked: the ruggedized stainless steel pressure valve. This small yet powerful component is essential for ensuring equipment longevity, reliability, and hygienic compliance in the most demanding industrial conditions.

What is Industrial Touchscreen Computers?

Industrial stainless steel touchscreen computers are designed to withstand harsh environments. They are used in various industries, including manufacturing, oil and gas, food processing, and pharmaceuticals. These computers facilitate seamless human-machine interaction, allowing operators to perform tasks more efficiently. However, their exposure to harsh conditions can lead to component failure if not adequately protected.

Industrial environments are notorious for their challenging conditions. Dust, moisture, temperature fluctuations, and vibration are just a few of the factors that can affect the performance of industrial touchscreen computers. Without proper protection, these elements can lead to malfunctions, downtime, and costly repairs.

What Is a Ruggedized Stainless Steel Pressure Valve?

How It Works

- • Vents excess internal pressure outward to prevent bulging or seal damage.

- • Admits filtered air when a vacuum is forming inside due to rapid cooling.

- • Blocks ingress of water, dust, and other particles even while adjusting pressure.

Materials & Design

Why Are Pressure Valves Essential for Industrial Touchscreen Computers?

Without a Pressure Valve:

- • Heat buildup can cause internal air to expand, leading to excessive internal pressure that may warp the enclosure or damage seals.

- • Sudden cooling during cold washdowns can create a vacuum, pulling water or airborne contaminants into the system.

- • Unequal pressure can lead to internal condensation, clouding displays or corroding sensitive electronics.

With a Pressure Valve:

Key Benefits of Stainless Steel Pressure Valves in Industrial PCs

1. Prevent Damage and Downtime

2. Enhance Reliability and Safety

3. Extend Equipment Lifespan

4. Support Sterility and Hygiene Standards

Real-World Applications

Food & Beverage Processing

In the food processing industry, maintaining hygiene and preventing contamination are top priorities. Stainless steel pressure valves prevent moisture ingress, ensuring that touchscreen computers remain operational without compromising food safety standards.

Pharmaceutical Manufacturing

Pharmaceutical environments require strict control over contamination and environmental conditions. Stainless steel pressure valves play a crucial role in maintaining the integrity of industrial touchscreen computers, ensuring compliance with industry regulations.

Oil & Gas Industry

Manufacturing Automation

In manufacturing facilities, dust and debris are common. Stainless steel pressure valves help keep these elements out of the computer enclosures, ensuring that operations run smoothly without interruptions.

Conclusion

In industries where hygiene, uptime, and long-term reliability are paramount, ruggedized stainless steel pressure valves are not just optional—they are mission-critical. Integrating them into your industrial computing solution ensures maximum durability, minimal downtime, and full compliance with industry regulations—ultimately safeguarding the technology that drives modern industry forward.