What Are Heatsinks? Why Fanless Industrial Computers Use Them

Time:2025-06-11 15:34:38

Visit:303

In the world of technology, maintaining the optimal temperature of electronic devices is crucial not only for performance but also for their longevity. When devices overheat, it can lead to a decline in performance, hardware malfunctions, or even permanent damage. This is why thermal management is an essential aspect of electronic design. Among the various methods and components used to keep devices cool, one stands out for its effectiveness and simplicity: the heatsink. Heatsinks are integral to the cooling process, particularly in environments that demand reliability and quiet operation, such as fanless industrial computers. Let's delve deeper into this fascinating topic to understand the mechanics of heat dissipation and passive cooling.

The design of a heatsink typically includes fins or ridges that increase the surface area available for heat transfer. The increased surface area allows more air to come into contact with the heatsink, enhancing the rate of heat dissipation. As air flows over these fins, it carries away the heat, allowing the device to maintain a safe temperature. The process of convection, where the heated air rises and is replaced by cooler air, further aids in the cooling process, making heatsinks incredibly effective in passive cooling solutions.

As technology continues to evolve, the demand for efficient and reliable cooling solutions like heatsinks will only grow, making them an indispensable component in the world of electronics. The ongoing development of new materials and designs will likely enhance the performance of heatsinks, meeting the ever-increasing thermal demands of modern electronic devices.

What Are Heatsinks?

How Do Heatsinks Work?

The design of a heatsink typically includes fins or ridges that increase the surface area available for heat transfer. The increased surface area allows more air to come into contact with the heatsink, enhancing the rate of heat dissipation. As air flows over these fins, it carries away the heat, allowing the device to maintain a safe temperature. The process of convection, where the heated air rises and is replaced by cooler air, further aids in the cooling process, making heatsinks incredibly effective in passive cooling solutions.

What Are the Different Types of Heatsinks?

- • Active Heatsinks: These heatsinks include fans or blowers to increase airflow and enhance heat dissipation. They are commonly found in personal computers and gaming consoles where high performance is necessary and noise levels are less of a concern. The active cooling provided by fans allows these systems to handle higher heat loads, making them suitable for environments where performance is a priority.

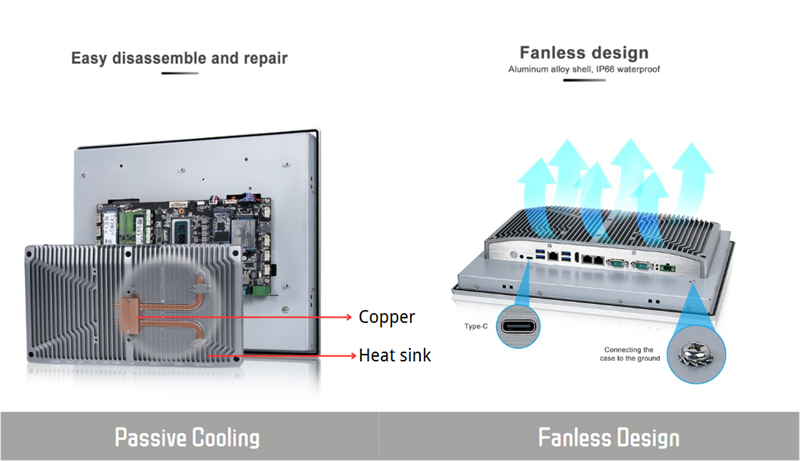

- • Passive Heatsinks: These rely solely on natural convection and radiation to dissipate heat. Passive heatsinks are often used in environments where noise or mechanical reliability is a concern, such as in fanless industrial computers. Without moving parts, passive heatsinks offer a silent and maintenance-free solution, making them ideal for applications requiring continuous, reliable operation in challenging conditions.

The Role of Heatsinks in Heat Dissipation

- • Increased Surface Area: The fins on a heatsink increase the surface area available for heat transfer, allowing more heat to be dissipated more quickly. This increased surface area is vital for effective heat dissipation, especially in passive systems where airflow is limited to natural convection.

- • Convection and Radiation: By promoting natural convection, heatsinks help circulate air around the device. As heated air rises, cooler air takes its place, creating a continuous cycle that aids in cooling. Additionally, they radiate heat away from the device, further contributing to cooling. This dual mechanism of convection and radiation makes heatsinks an efficient solution for managing thermal loads in a wide range of applications.

Why Fanless Industrial Computers Use Heatsinks

Benefits of Fanless Designs with Heatsinks

- • Reliability: Without moving parts, fanless systems are inherently more reliable. The use of passive heatsinks ensures these systems can operate continuously without the risk of fan failure, which can be caused by dust accumulation or mechanical wear. This reliability is crucial in industrial settings where system downtime can result in significant operational losses.

- • Noise Reduction: Fans can generate significant noise, which can be disruptive in certain environments. Fanless designs with passive heatsinks operate silently, making them ideal for noise-sensitive applications. Silence is particularly important in environments like hospitals, laboratories, or offices where quiet operation is essential for productivity and comfort.

- • Reduced Maintenance: Fans require regular maintenance to prevent dust accumulation and mechanical wear. Fanless systems with heatsinks eliminate this requirement, reducing maintenance needs and costs. This reduction in maintenance not only lowers operational costs but also increases system uptime, which is critical in industrial applications where continuous operation is often required.

Applications of Fanless Industrial Computers

- • Medical Devices: In healthcare settings, noise-free operation is essential, and fanless computers with heatsinks are used to power medical imaging and patient monitoring systems. These systems require continuous operation and reliability, as any failure could impact patient care and outcomes.

- • Automated Industrial Systems: In factories, fanless computers control and monitor production lines, benefiting from the durability and low maintenance of passive cooling systems. The ability to withstand harsh industrial environments without the need for frequent maintenance makes them invaluable in manufacturing processes where downtime can be costly.

- • Outdoor Digital Signage: Exposed to the elements, outdoor digital displays rely on fanless designs with heatsinks to ensure continuous operation in varying environmental conditions. These systems must withstand temperature fluctuations, dust, and humidity, all of which are managed effectively through passive cooling.

As technology continues to evolve, the demand for efficient and reliable cooling solutions like heatsinks will only grow, making them an indispensable component in the world of electronics. The ongoing development of new materials and designs will likely enhance the performance of heatsinks, meeting the ever-increasing thermal demands of modern electronic devices.