Application of Fanless IPC in Wind Power Generation

Industry Background:

With the accelerating process of global warming, the concept of caring for the earth, environmental protection and energy saving has become more and more popular. As a kind of renewable and clean energy, wind energy is becoming a new energy vigorously promoted by all countries in the world under the situation of energy shortage and serious pollution in the world today. The two main components in a wind power system are wind turbines and generators. Wind turbines are developing towards variable pitch adjustment technology, and generators are developing towards variable speed constant frequency power generation technology. This is the development trend of wind power generation technology, and it is also the core technology of wind power generation today. The pitch adjustment method is to change the angle between the windward surface of the blade and the longitudinal axis of rotation, thereby affecting the force and resistance of the blade, limiting the increase of the output power of the fan in strong wind, and maintaining the output power constant. Variable-speed constant-frequency wind turbines often use AC excitation doubly-fed generators, which are similar in structure to wound induction motors, except that slip rings and brushes are added to the rotor windings. Thus, the rotor speed is related to the excitation frequency. , so that the internal electromagnetic relationship of the doubly-fed generator is different from that of the asynchronous generator and the synchronous generator. However, variable-speed constant-frequency wind turbines have certain characteristics of asynchronous machines and synchronous machines, both of which require stable operation of the system in harsh environments.

Application Requirement:

In order to ensure continuous and safe power supply, wind turbines must continuously and reliably generate electricity through wind energy conversion under extreme conditions, and can be controlled and monitored in a timely and effective manner. The power plant information management system is designed to collect raw data from hundreds of wind turbines and turn it into intelligent data information. At the same time, the processed intelligent data information must be able to be stored for a long time in order to analyze the historical records and further improve the power generation efficiency.

Solutions and Product:

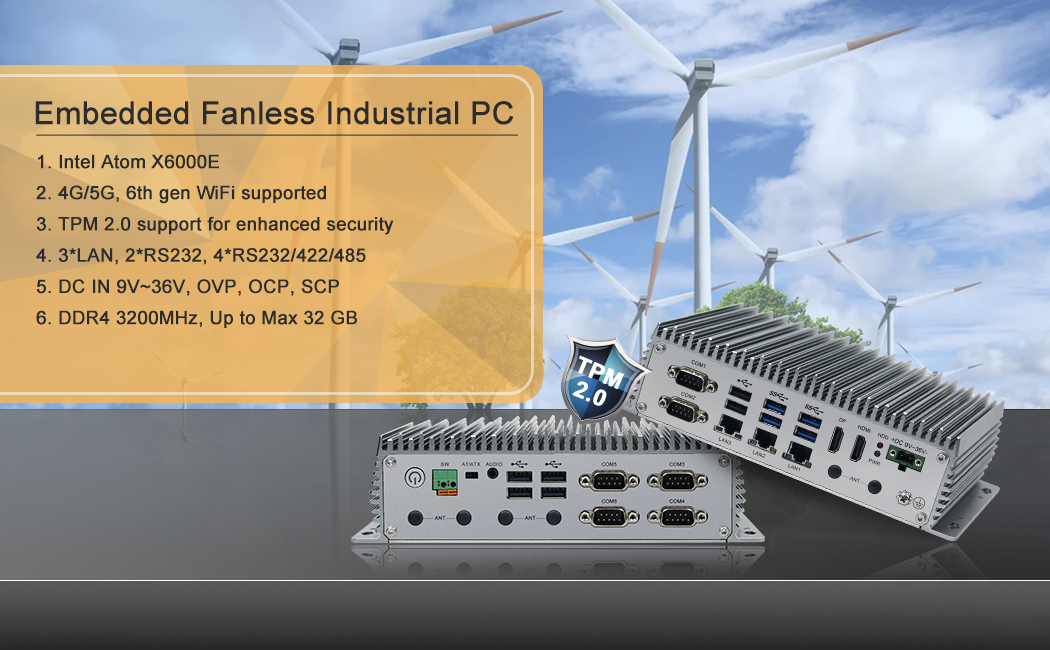

InnoAioT embedded industrial computer EFIC-2000 series, based on Intel Atom X6000E series platform, using high-performance, low-power x6000E series processors; Support Gigabit Ethernet/WIFI/4G/5G network; Onboard DDR4 memory supports up to 32G; Support SATA and M.2 storage; Extensible IO interface includes: 3 network ports, 10 USB, 6 serial ports, 2 HDMI, and 8xDIO interfaces. EFIC-2000 series are built in strict accordance with industrial standards, which has a good electromagnetic compatibility and strong environmental adaptability; fanless design, energy saving and environmental protection, meet the requirements of storage and 24-hour continuous and reliable operation.

Product Features:

1. Reliable Performance and Wide Operating Temperature

EFIC-2000 adopts Intel Atom X6000E series processor, with wide operating temperature (-20°C -70°C), anti-static (ESD), surge protection, shock and shock resistance, fanless design and durable structure, can Provides reliable performance against the extreme environmental conditions on wind turbine sites.

2. 3 Intel GbE Network Ports

The EFIC-2000 features 3 Intel I225V Ethernet controllers that provide a stable connection to SCADA servers with gigabit performance, and can transmit various types of power generation data such as: power production, temperature, wind speed, voltage, current, and rotational speed .

3. Flexible I/O expansion

Users can expand various I/O interfaces according to their needs, including: DIO, network port, CAN, COM, etc. Customers can detect and control equipment through the expanded digital I/O ports, such as the gate switch of the wind turbine tower.

4. Small Size and Easy lnstallation.

Support bracket and DIN rail installation, easy for customers to install, test and wire in small control cabinets.