Empower Seafood Automation with InnoAioT's Waterproof Panel PC

Industry: Food Processing / Seafood Industry

Application: Automated Seafood Processing Line

Solution: InnoAioT WPC Series – Stainless Steel Waterproof Industrial Panel PCs

Meeting the Demands of Modern Food Processing with Reliable and Hygienic Automation

As global demand for processed seafood continues to rise, seafood processing plants—particularly in regions like South America—are rapidly expanding operations. However, this growth brings new challenges: the need to ensure high hygiene standards, maintain production efficiency, and achieve full traceability across all stages of processing.

In seafood processing, contamination risks are high due to the constant presence of moisture, organic residue, and extreme temperature variations. This makes it critical for equipment to meet stringent sanitation requirements. Automation systems used in these environments must not only perform reliably but also withstand frequent high-pressure cleaning and resist corrosion caused by exposure to salt, oil, and cleaning agents.

To overcome these challenges, a seafood processing facility in South America turned to InnoAioT’s WPC Series waterproof industrial panel PCs. These rugged and highly sanitary computers are designed specifically for demanding food-grade environments, providing a stable and efficient solution for digitalizing processing lines, improving production transparency, and enhancing operational control.

Smart Seafood Processing: From Weighing to Packaging with Traceable Automation

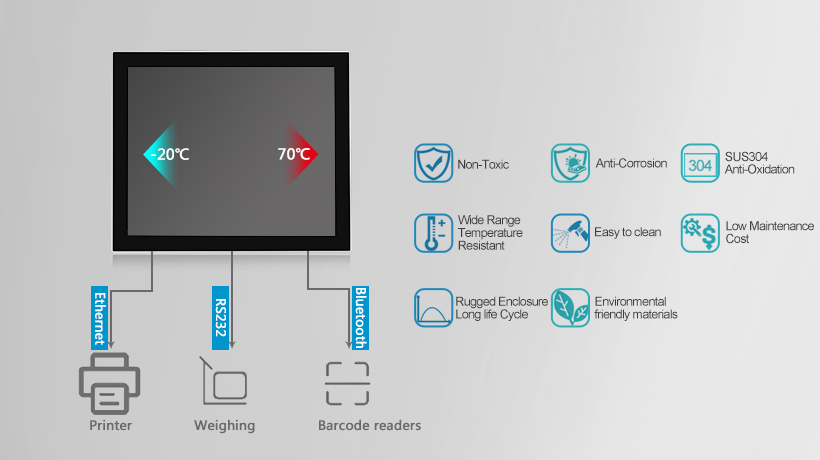

The automated seafood processing system integrates several critical functions: weighing, labeling, packaging, inspection, and batch tracking. To support these workflows, InnoAioT’s fanless panel PCs offer a combination of durability, powerful processing performance, and rich I/O options.

Each workstation along the production line is equipped with an IP66/IP69K-rated industrial panel PC that enables real-time data capture and interaction with weighing scales, barcode scanners, label printers, and PLCs. The system is resistant to water ingress and can be sanitized using high-pressure washdowns without risk of corrosion or system failure.

This significantly enhances product traceability—from catch to packaging—ensuring compliance with food safety regulations and facilitating export certification. Operators can also monitor production metrics via the intuitive multi-touch display, improving overall responsiveness and minimizing downtime.

Engineered for Hygiene and Durability: The Power of InnoAioT WPC Series

The food industry imposes stricter environmental requirements than most industrial automation sectors. Not only must the equipment be dustproof and waterproof, but it must also resist corrosion and bacterial growth. As a result, stainless steel—especially food-grade SUS304 or SUS316—is the material of choice for enclosures in food processing.

InnoAioT's waterproof touch screen panel PCs are purpose-built for such environments. They feature a fully sealed stainless steel housing, industrial-grade M12 I/O connectors, and fanless thermal design to eliminate contamination risks associated with air intake. The seamless housing ensures bacteria do not accumulate in gaps or crevices, while the IP69K rating enables safe operation during daily high-temperature, high-pressure cleaning procedures.

- • Rugged 304/316 stainless steel housing with IP66/IP69K protection for extreme sanitation

- • 17” TFT LED display (1280x1024 resolution) with 10-point capacitive touch

- • Fanless Intel® Celeron® J1900 2.0GHz processor for silent, reliable performance

- • Rich I/O connectivity: 2 x LAN, 2 x COM (RS232/422/485 switchable), M12 connectors

- • EMC protection: 8KV static resistance, 600W surge protection

- • Certified for IEC 61076-2-101 standard for industrial-grade reliability

Transforming Seafood Processing through Smart Automation

By adopting InnoAioT’s waterproof industrial panel PCs, the seafood processing plant achieved significant improvements across multiple dimensions:

- • Cost Reduction: Automation reduced manual labor and improved consistency, lowering operational costs.

- • Process Accuracy: Advanced systems enable precise portioning, grading, and packaging.

- • Real-Time Monitoring: Enhanced data processing allows for instant updates, ensuring efficient workflow adjustments.

- • Hygiene Assurance: The stainless steel, waterproof design ensures continuous compliance with food safety standards.

- • Traceability & Compliance: Batch number tracking and system integration provide end-to-end product transparency.

The combination of advanced hardware and robust hygiene protection makes InnoAioT’s WPC Series the ideal solution for modern food automation facilities. Whether used in seafood, meat, beverage, or pharmaceutical processing, these systems ensure reliability, safety, and long-term performance.

Learn More about InnoAioT WPC Series – Your Reliable Partner in Food Processing Automation

Optimize hygiene. Maximize efficiency. Enable smarter food-grade manufacturing.

Contact InnoAioT to explore the complete WPC Series solution portfolio.