Streamlining Pharmaceutical Operations with InnoAioT’s Stainless Steel Panel PC

Overview

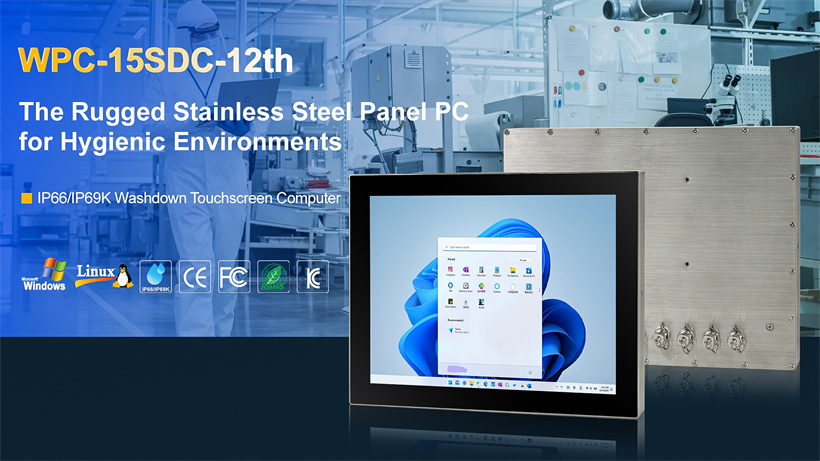

To address these challenges, a leading U.S.-based manufacturer of sterile filling and inspection equipment partnered with InnoAioT to deploy the WPC-15SDC-12th, a 15.6” IP66/IP69K stainless steel panel PC designed for hygiene-critical environments. This case study explores how InnoAioT’s rugged computing solution enhanced sanitation readiness, improved uptime, and ensured precise control in GMP-regulated pharmaceutical production lines.

Challenges

- • Needed an industrial-grade panel PC to endure daily high-pressure, high-temperature washdowns and chemical disinfectants

- • Required a touchscreen lock function to disable touch input during sanitation while keeping systems operational

- • Needed protection against internal condensation caused by rapid temperature and humidity fluctuations

- • Sought a glove-friendly, anti-reflective touchscreen for clear and responsive operation in sterile cleanrooms

- • Installation demanded versatile mounting options for seamless integration into existing production equipment

Solutions

- • InnoAioT WPC-15SDC-12th IP66/IP69K-rated stainless steel panel PC

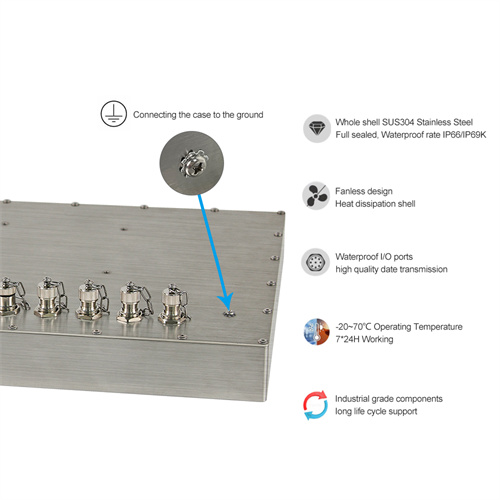

- • SUS316 stainless steel enclosure for superior corrosion and chemical resistance during daily sanitation

- • Touchscreen ON/OFF control to lock touch input during cleaning without shutting down the system

- • Integrated pressure relief valve (SUS316 vent) to balance internal pressure and prevent condensation damage

- • 15.6” Full HD optically bonded PCAP touchscreen with glove-friendly operation, scratch resistance, and anti-reflective coating

- • Flexible mounting support for both VESA and yoke options, enabling fast integration into existing pharmaceutical machinery

Benefits

- • No minimum order quantity (MOQ) for scalable implementation

- • Short lead times for quick deployment and urgent replacements

Company Background

The customer is a U.S.-based pharmaceutical equipment manufacturer specializing in sterile filling, inspection, and packaging systems. Their solutions support pharmaceutical production facilities worldwide, ensuring product safety, regulatory compliance, and operational efficiency. With increased demand for sterile processing and stricter hygiene protocols, the company required computing hardware that could survive aggressive sanitation procedures without compromising performance or integration flexibility.

Challenges

Withstanding Harsh Sanitation in GMP Environments

The customer’s systems operate in GMP-certified cleanrooms, undergoing daily sanitation with high-pressure, high-temperature sprays and strong disinfectants. Conventional panel PCs often suffered corrosion, water ingress, and early failure under these conditions.

Avoiding Accidental Touch Inputs During Cleaning

During washdowns, operators needed the computing system to continue running while blocking unintended touchscreen inputs from water or cleaning tools. Without this capability, sanitation cycles risked interrupting ongoing production or causing data errors.

Preventing Internal Moisture Damage

Rapid temperature changes between production and cleaning cycles caused internal condensation, which could damage sensitive components and shorten device lifespan.

Maintaining Usability for Gloved Operators

Workers in cleanroom conditions wear gloves at all times, making touch interaction less responsive. Bright lighting and reflective surfaces further reduced screen visibility.

Fitting into Space-Constrained Equipment Layouts

The customer’s equipment design left limited space for hardware integration, requiring a compact and adaptable mounting solution.

Solutions

Hygienic SUS316 Stainless Steel Design

The WPC-15SDC-12th features a fully sealed SUS316 stainless steel enclosure, offering exceptional corrosion resistance and durability in aggressive washdown environments.

Touchscreen Lock Functionality

A physical control allows operators to disable touchscreen input during sanitation, preventing accidental commands while keeping essential processes running in the background.

Pressure Relief Valve for Moisture Control

The integrated SUS316 pressure relief vent equalizes internal air pressure, reducing condensation risk and protecting internal electronics.

Glove-Friendly Anti-Reflective Touchscreen

The 15.6” Full HD PCAP touchscreen is optically bonded for clarity, supports glove operation, resists scratches, and reduces glare for better visibility in bright cleanrooms.

Flexible Mounting Options

With support for both VESA and yoke mounting, the panel PC can be quickly integrated into existing pharmaceutical systems without complex modifications.

The Benefits

- • By replacing conventional panel PCs with InnoAioT’s WPC-15SDC-12th, the customer achieved:

- • Improved sanitation resilience – No corrosion or water ingress despite daily washdowns

- • Reduced downtime – Touchscreen lock feature prevented accidental interruptions during cleaning

- • Enhanced operator efficiency – Clear, responsive display even for gloved personnel

- • Lower maintenance costs – Condensation prevention extended device lifespan

- • Seamless integration – Flexible mounting enabled quick installation without redesign

Conclusion