Accelerating Medical Automation with Stainless Steel Industrial Panel PCs

The Challenge

- • Medical rubber stoppers require strict sterilization before pharmaceutical packaging, with precise temperature control.

- • Manual monitoring methods couldn't meet the demands for automation, real-time control, and regulatory compliance.

- • Space constraints in the electrical control cabinet required a compact, reliable, and hygienic computing solution.

- • Existing computing platforms lacked industrial durability, long-term availability, and integration capabilities.

The Solution

- • Deployed InnoAioT's PPC-215WCC stainless steel panel PC as the upper-layer control system, running Windows 10 IoT and industrial configuration software.

- • Connected to the PLC via RS485 for real-time temperature monitoring and process automation.

- • Built with an IP66 SUS304 stainless steel front panel, suitable for high-pressure washdowns and sterile environments.

- • Integrated dual Gigabit LAN, wide voltage DC input (9~36V), and robust power protection for stable operation.

- • Enabled real-time visualization, alarm tracking, and historical data logging for full system transparency.

The Benefit

- • Achieved precise temperature control, automated sterilization, and streamlined HMI operation.

- • Ensured compliance with stringent pharmaceutical hygiene and safety standards.

- • Reduced system downtime with rugged, long-life industrial hardware.

- • Simplified system integration with a space-efficient, all-in-one design.

- • Supported the digital transformation of pharmaceutical production with scalable automation tools.

The Company

As pharmaceutical companies strive to meet evolving global health standards, equipment manufacturers play a vital role in building automation-ready solutions. With increasing emphasis on lean production, error prevention, and real-time monitoring, the integration of industrial computing into pharmaceutical systems is no longer optional—it’s a necessity.

InnoAioT is committed to accelerating pharmaceutical automation by providing industrial-grade panel PCs and embedded computing platforms tailored for harsh, regulated environments. Through its proven engineering capabilities and customer-driven approach, InnoAioT empowers OEMs to upgrade their legacy equipment into intelligent, connected systems that help deliver safer, faster, and more cost-effective pharmaceutical production.

The Challenge

In the pharmaceutical manufacturing sector, achieving high standards for drug quality, cost efficiency, and regulatory compliance demands more than traditional manual operations. As production scales increase and industry competition intensifies, pharmaceutical companies are turning to automation to enhance productivity and consistency.

One OEM specializing in medical rubber stopper sterilization equipment faced significant challenges. The process of sterilizing and washing rubber stoppers—an essential step before pharmaceutical packaging—requires precise control over temperature and timing. Manual temperature monitoring and disconnected systems could no longer guarantee the required sterilization standards.

Additionally, the OEM needed a computing solution that could integrate with PLC systems for process automation, provide real-time monitoring and visualization, support human-machine interaction, and fit within space-constrained control cabinets. With increasing demand for automation, their current consumer-grade or outdated computing hardware fell short on reliability, ruggedness, and real-time data handling—especially under the demanding environmental and hygiene conditions of pharmaceutical manufacturing.

The OEM sought a reliable industrial computing platform that could serve as the “brain” of their equipment, manage high-stakes automation logic, and ensure both quality control and regulatory compliance.

The Solution

InnoAioT provided a purpose-built, industrial-grade solution designed to meet the rigorous standards of the pharmaceutical industry. After a detailed technical assessment of the equipment’s control box dimensions, I/O needs, and hygienic requirements, InnoAioT recommended its PPC-215WCC stainless steel industrial panel PC as the upper-layer computing interface.

This fanless panel PC is engineered with a SUS304 stainless steel front bezel and IP66 ingress protection, allowing it to withstand high-pressure water, steam, and chemical washdowns—ideal for sterilization environments. It supports Windows 10 IoT, which makes it compatible with various SCADA and industrial HMI software while allowing for secondary development for custom automation needs.

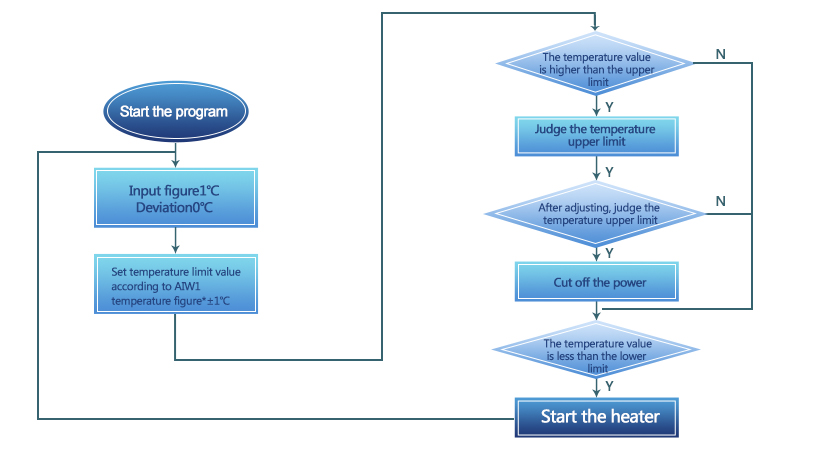

The PPC-215WCC connects seamlessly to the PLC via its integrated RS485 serial port, enabling real-time data acquisition, temperature monitoring, and process control. Dual Gigabit Ethernet ports support backend server communication for centralized monitoring. The built-in wide voltage DC input (9~36V) and protection against overcurrent, overvoltage, and reverse polarity ensure system stability in fluctuating power conditions.

The rugged hardware was paired with distributed configuration software, providing operators with an intuitive interface to monitor and control temperature curves, view historical alarms, track process variables, and manage sterilization cycles with high precision.

The Benefit

- • By integrating InnoAioT’s PPC-215WCC industrial panel PC into its rubber stopper sterilization system, the OEM achieved significant operational improvements:

- • Enhanced Automation: Real-time PLC communication and intuitive HMI interfaces enabled precise control of sterilization parameters and reduced operator error.

- • Regulatory Compliance: With reliable temperature monitoring and traceable alarm logs, the system meets strict pharmaceutical standards.

- • Hygienic Safety: The IP66-rated stainless steel front panel supports thorough washdown protocols without compromising device functionality.

- • Long-Term Reliability: Industrial-grade components ensure a longer product lifecycle compared to consumer-grade alternatives, minimizing downtime and unexpected maintenance.

- • Flexible Integration: The panel PC’s slim profile and versatile mounting options made installation simple even in space-limited electrical control cabinets.

- • This solution enables the OEM to deliver smarter pharmaceutical sterilization equipment with higher levels of automation, efficiency, and compliance—equipping drug manufacturers with the digital tools needed for modern lean production.