Smart Tire Vulcanization Automation with InnoAioT Industrial Panel PC

The Challenge

- • Tire vulcanization requires precise control of temperature, pressure, and timing to ensure product quality.

- • Traditional control systems relied on manual operations and lacked automation and real-time process visibility.

- • The harsh production environment demanded durable, fanless, and dust-proof computing equipment.

- • The control host needed high processing power to handle real-time data and interface with PLC systems.

The Solution

- • InnoAioT provided its rugged industrial panel PC as the host computer for the vulcanization control system.

- • The PPC panel PC collects process data from PLCs and enables operators to manage formulas via HMI software.

- • The 17" capacitive touch display with IP66 front panel ensures intuitive operation and environmental resistance.

- • Equipped with Intel® 8th Gen Core™ processors and TPM 2.0, it delivers industrial-grade performance and security.

The Benefit

- • Enabled intelligent automation and stable vulcanization control with reduced manual intervention.

- • Improved production efficiency, process consistency, and product quality.

- • Delivered a durable, compact, and secure solution suitable for harsh industrial environments.

- • Provided a scalable platform for smart tire manufacturing and future upgrades.

The Challenge

As the automotive industry continues to grow rapidly, so too does the demand for high-quality tires. A critical step in tire manufacturing is the vulcanization process, which determines the tire's strength, elasticity, and durability. Successful vulcanization depends heavily on precise control over temperature, pressure, and time—known as the “three elements of vulcanization.”

Traditionally, tire vulcanization relied on control systems composed of numerous manual switches, indicator lights, and mechanical buttons. These systems not only required constant operator input but also posed limitations in accuracy, response time, and operational efficiency.

To meet the demands of modern high-volume production and consistent product quality, manufacturers are shifting toward intelligent control systems that can automatically monitor and adjust process parameters in real time. This transformation calls for a high-performance computing platform capable of operating reliably in harsh industrial environments while supporting the automation and smart management of tire curing lines.

Key system requirements included:

- • A high-performance control host for processing complex data and executing automated control task

- • Durable industrial-grade hardware that could withstand high temperatures, dust, and vibration on the factory floor

- • A user-friendly interface to allow for intelligent management of formula parameters and process settings

The Solution

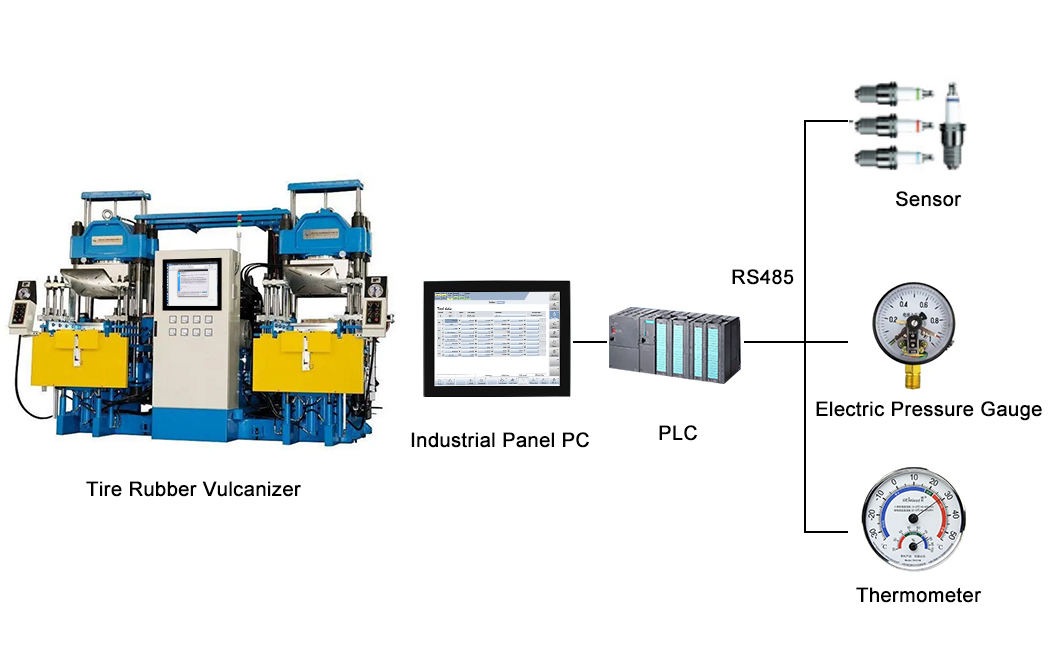

To enable fully automated and intelligent control of the tire curing process, InnoAioT delivered an edge computing solution based on its PPC series industrial panel PC.

Serving as the host computer in the system architecture, the selected PPC model monitors the entire vulcanization workflow, including real-time temperature and pressure data acquisition from PLCs. Operators can use the panel’s capacitive multi-touch interface and configuration software to adjust process formulas and manage parameters, effectively achieving intelligent, automatic production control.

Built for industrial environments, the PPC panel PC features a fanless recessed structure, aluminum alloy chassis, and front IP66 protection, ensuring durability and reliable operation in rugged production settings. With support for Intel® 8th Gen Core™ processors, it provides the high-performance computing power necessary to manage real-time processing tasks and interface with various automation equipment.

Product Highlights:

- • 17” 1280×1024 TFT LED display, with 10-point capacitive touchscreen for smooth operator interaction

- • Pure flat front bezel, IP66-rated for waterproof and dustproof protection

- • Intel® 8th Gen Core i3/i5/i7 processor, ensuring industrial-grade performance and fast data handling

- • Fanless design and aluminum alloy housing, with ground protection for electrical safety

- • TPM 2.0 onboard module, delivering hardware-level security and data integrity

- • Wide-range 9–36V DC in

The Benefit

By deploying InnoAioT’s industrial panel PC, the tire manufacturer successfully transitioned from outdated manual systems to an advanced, fully automated vulcanization control solution.

The upgraded system not only delivered improved process stability and reduced error rates, but also helped the customer achieve leaner operations and more consistent product quality. The intuitive HMI design empowered operators to make real-time adjustments, while the rugged construction of the device ensured long-term reliability in challenging environments.

- • With InnoAioT’s industrial-grade computing solution in place, the manufacturer benefited from:

- • Higher production efficiency through real-time process monitoring and automation

- • Optimized product quality by ensuring accurate vulcanization control parameters

- • Reduced downtime and manual intervention, streamlining operations and lowering labor costs

- • Scalable smart factory capabilities, laying a foundation for future industrial upgrades

InnoAioT’s PPC series proved to be the ideal control platform—delivering the performance, durability, and intelligent automation support required to bring next-generation tire manufacturing to life.