The Role of Industrial Computers in Smart Manufacturing

In the process of Industry 4.0, industry manufacturing enters the highly connected, intelligent, and efficient system. Smart factories are where machines communicate with each other to optimize production processes. However, this process also introduces several challenges, such as real-time data processing, connectivity, and communication.

Industrial computers are the backbone of Industry 4.0, enabling the integration of advanced technologies like IoT, AI, and big data into manufacturing processes. Without them, the interconnected ecosystem of Industry 4.0 would break down, leading to isolated systems and inefficient workflows.

Industrial computers play an essential role in smart manufacturing, their powerful data processing capabilities and adaptability to harsh environments enhance the productivity and intelligence in industry automation.

What Are Industrial Computers?

Industrial computers are rugged computers designed specifically for use in harsh industrial environments. Unlike traditional computers, these devices are built to withstand extreme temperatures, dust, moisture, and vibrations. They come equipped with industrial touch screens, making them highly interactive and user-friendly.

The Essential Role of Industrial Computers in Smart Manufacturing

Improving Efficiency and Productivity in Manufacturing with Industrial PCs

Smart manufacturing leverages data and connectivity to enhance efficiency and productivity. Industrial PCs= play a crucial role in this transformation. With advantages such as flexibility, stability, and scalability, industrial PCs enable real-time data collection and analysis. This data can be analyzed to identify patterns, predict downtime, and optimize operations. By processing data on-site, manufacturers can make faster, more informed decisions.

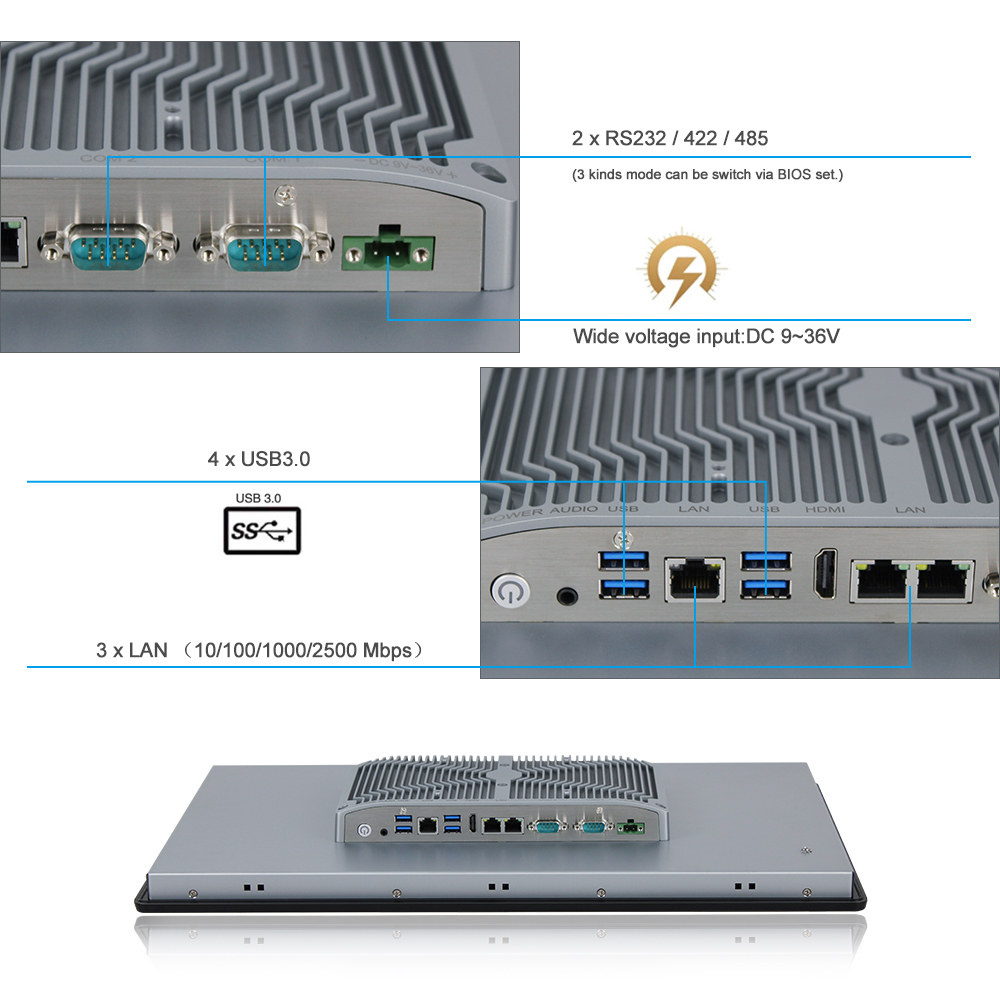

Industrial PCs are equipped with multiple I/O ports, allowing easy connectivity between various devices and systems. This strong collaborative capability helps reduce costs.

Moreover, integrating industrial computing into manufacturing processes enables better control and automation. Industrial computers can interact with machines to monitor operations, adjust parameters, and ensure everything runs smoothly. This control is essential for maintaining quality and efficiency.

Quickly Adapt to Changes in Production Demands

Industrial PCs are designed to withstand harsh conditions, much like the computers they are part of. Whether exposed to chemicals, water, or extreme temperatures, these devices continue to operate reliably, ensuring continuous production.

With industrial PCs, whether it's changing production lines or scaling operations, these devices provide the flexibility needed to respond to market changes without significant downtime or costs.

Real-World Applications of Industrial PCs in Smart Manufacturing

Industrial panel PCs have strong capabilities in industrial smart manufacturing and are widely applicable. From automotive manufacturing to the food industry, industrial PCs enable real-time data analysis and intelligent control.

-

Food and Beverage Industry

Industrial PCs play a significant role in production, packaging, and quality control in the food and beverage industry. For example, a large food processing company uses industrial PCs combined with vision inspection systems and sensors for quality detection. They can detect product appearance defects, food composition, and hygiene conditions.

-

Automotive Manufacturing

In the automotive industry, for instance, through PLC and SCADA integration, industrial PCs monitor production line status in real-time, ensuring efficient and precise operations. With data processing and intelligent control, productivity can increase by 20%. Their ability to handle complex tasks in real-time is invaluable in this fast-paced environment.

-

Energy Industry

In oil and gas extraction, industrial PCs are used to monitor equipment status and perform predictive maintenance. They can identify potential equipment failures, preventing sudden shutdowns during operations.

Enhancing Productivity and Maximizing Efficiency with InnoAioT Industrial Computers

InnoAioT industrial PCs are designed to meet the demands of modern smart manufacturing environments. InnoAioT industrial PCs continue to innovate and develop, offering different processor options. Whether it's Intel® Celeron, Intel® Atom, or Intel® Core, paired with InnoAioT's self-developed industrial motherboards, they can operate quickly and efficiently in smart manufacturing environments.

-

High-Performance Memory for Smart Manufacturing

InnoAioT industrial PCs support up to 64GB DDR5 4800MHz memory, helping to easily handle high-intensity data processing tasks in large-scale industrial smart manufacturing. Additionally, equipped with ECC error correction technology, they monitor and automatically correct memory errors in real-time, effectively preventing data corruption and system crashes.

-

Faster and More Flexible Storage for Industrial Automation

InnoAioT industrial computers offer M.2 NVMe/SATA SSD dual storage options, enabling high-speed data storage and access, ensuring real-time production data. The convenient rear shell design supports quick memory and hard drive replacement, meeting efficient upgrade needs.

-

Designed for Harsh Industrial Automation Environments

Featuring a fanless structure and robust aluminum casing, these devices ensure stable operation in harsh environments with dust, vibrations, and oil. They support Windows, Linux, and Ubuntu systems and offer a variety of sizes from 15 inches to 23.8 inches, flexibly adapting to diverse industrial scenarios. With a wide operating temperature range (-20~70°C/-22~176°F), they ensure efficient and reliable smart production even under extreme temperature conditions.

-

Strong Connectivity Driving Industrial Automation

Industrial computers are crucial for connecting devices, enabling seamless communication, and driving automation. InnoAioT industrial PCs support 4G/5G communication and offer optional WIFI and Bluetooth configurations. Additionally, they provide multiple I/O ports, ensuring integration with various devices and systems, further enhancing their practicality in smart manufacturing environments.

Conclusion

Industrial computers are at the heart of smart manufacturing, providing the necessary tools for enhanced productivity, data management, and process control. Their robust design and advanced features make them indispensable in modern manufacturing settings. As technology advances, these devices will continue to evolve, offering even greater capabilities and transforming the manufacturing landscape.

Incorporating InnoAioT industrial computers into your operations can significantly improve efficiency and productivity, making them a wise investment for any forward-thinking manufacturer.