The Best Industrial PC Setup according to your Industry Type

Industrial PCs are the backbone of modern industry. They power automation, control, and data collection. Choosing the right setup is crucial. It can significantly impact productivity and efficiency. Different industries have unique needs. A tailored industrial PC setup can meet these specific requirements. Harsh environments demand rugged solutions. Industrial PCs are built to withstand extreme conditions. From manufacturing to mining, each sector benefits from specialized computing solutions. The right industrial PC setup can reduce downtime and maintenance costs. It ensures continuous operation. Security is also a key consideration. Industrial PCs must protect against cyber threats. This guide will help you select the optimal industrial PC setup for your specific industry.

Industrial PCs: What Sets Them Apart

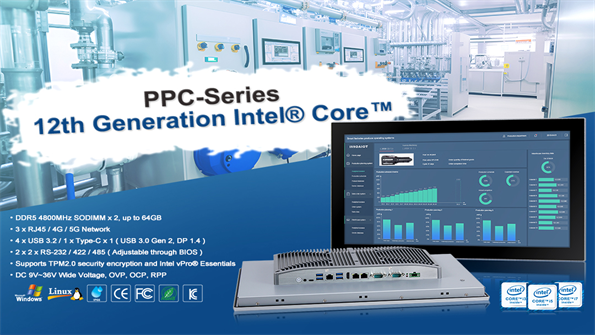

Industrial computers are distinct from regular computers in several ways. They are engineered for durability and reliability under harsh conditions. These PCs operate efficiently in extreme temperatures and resist dust and vibrations. They are built for environments that challenge normal computers. One of their core strengths is flexibility. Industrial computers can be configured with various I/O ports, supporting diverse equipment. This adaptability is vital for industry-specific needs. Beyond hardware, software is crucial too. Industrial PCs support a range of operating systems, such as Windows, Linux, and real-time OS, catering to different operational demands.

Key characteristics that distinguish industrial PCs include:

- • Rugged design for harsh environments

- • Fanless cooling systems to prevent dust intake

- • Variety of mounting options for versatile applications

These features collectively make industrial computing solutions essential for operations requiring reliability and longevity. Their robust nature ensures uninterrupted performance and seamless integration within industry infrastructures.

Key Factors to Consider for an Industrial PC Setup

Choosing the right industrial PC involves considering several critical factors. These elements ensure your setup meets your industry's unique demands.

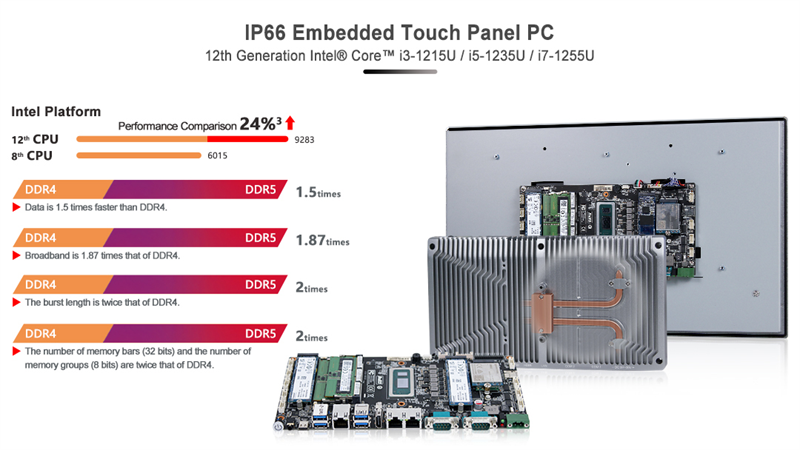

Processing power is a primary consideration. Depending on your applications, you'll need varying levels of CPU speed and memory capacity. High-performance tasks like machine vision may require greater resources.

Connectivity is another important aspect. Industrial computers often require numerous I/O ports to interface with peripherals and sensors. Ensure the PC can connect seamlessly with your existing infrastructure.

Environmental resilience is paramount. Determine the environmental conditions your PC must withstand, such as temperature extremes, dust levels, and vibrations. A rugged design will be necessary for harsh environments.

Consider the potential for expansion. Industrial PCs should accommodate future upgrades. This scalability is important as technology evolves and system requirements grow.

Here are key factors to consider:

- • Processing power for task requirements

- • Connectivity with existing systems

- • Environmental resilience for harsh conditions

- • Expansion capability for future needs

Customizability is also crucial. Your industrial PC should be tailored to your specific processes and operational requirements. This customization ensures efficiency and effectiveness. Investing in a comprehensive industrial computing solution ultimately boosts productivity and reduces downtime, offering significant long-term benefits for your business.

Industrial PC Setup by Industry Type

Different industries have unique needs for their industrial PC setups. Each sector requires specific solutions to enhance efficiency and productivity.

Selecting the right industrial PC depends heavily on the industry-specific requirements. From harsh environments to high processing power, each use case demands careful consideration to match operational goals.

Manufacturing and Automation

In the manufacturing sector, industrial panel computers are essential for automation and process control. They play a key role in managing robotics, assembly lines, and quality control systems. The need for real-time data processing is crucial. Industrial PCs must handle complex computations swiftly to ensure smooth operations. Durability is also vital in a manufacturing setting. PCs should withstand dust, vibrations, and temperature fluctuations common on factory floors.

Common features for this sector include:

- • High processing power for real-time tasks

- • Rugged design for environmental resilience

- • Multiple I/O ports for peripheral connectivity

Customization options enable integration with existing control systems. This flexibility ensures that industrial PCs meet the precise needs of the manufacturing process.

Oil, Gas, and Mining

The oil, gas, and mining sectors require industrial PCs that can withstand some of the harshest conditions. Extreme temperatures and rugged terrain demand resilient equipment. Reliable data management and automation are crucial. Industrial PCs facilitate operation monitoring, safety checks, and machine controls.

These PCs must be explosion-proof and meet specific industry certifications, like ATEX, for safety. Communication capabilities are essential for remote monitoring and data transmission in isolated locations.

Consider these features:

- • Explosion-proof designs for safety

- • Advanced communication capabilities

- • Certification for industry-specific needs

These attributes are vital for delivering consistent and safe operations under challenging conditions in the field.

Transportation and Logistics

Transportation and logistics industries depend heavily on precise data. Industrial PCs are instrumental in fleet management, shipping optimization, and route planning. These PCs must offer robust connectivity, as they often serve as central data hubs. They provide real-time tracking and status updates to streamline operations. Durability is key, as devices are subject to constant movement and varied weather conditions. Connectivity must be foolproof to ensure smooth operation across different logistics platforms.

Preferred features include:

- • Exceptional data processing for real-time tracking

- • Robust build for durability

- • Reliable connectivity for seamless data flow

With these features, industrial PCs optimize transit processes and improve decision-making in the logistics chain.

Food, Beverage, and Pharmaceutical

In the food, beverage, and pharmaceutical industries, precision and hygiene are critical. Industrial PCs must comply with strict regulatory standards and handle delicate processes. PCs in these sectors manage supply chains, production controls, and quality assurance. They must support frequent cleanings and operate in sanitized environments without impairing performance. Temperature control is a specific consideration, as processing environments might involve freezing or heating. Features to focus on are:

- • Compliance with hygiene and cleanliness standards

- • Temperature resilience for diverse processing needs

- • High precision data management for quality assurance

An effective setup ensures compliance and enhances product quality while minimizing waste.

Utilities and Energy

The utilities and energy sectors require continuous monitoring and control. Industrial PCs are essential for managing grid systems, renewable energy sources, and control centers. They must offer scalable solutions to handle expanding networks and increasing data volumes. Reliability and uptime are crucial, as any disruption can have widespread effects.

Industrial PCs should include features like:

- • Scalability for expanding operations

- • Robust uptime capabilities for continuous service

- • Resilience against external environmental factors

These features support secure and efficient energy management, vital for modern utility networks.

Smart Factories and Industry 4.0

As industries embrace Industry 4.0, smart factories demand cutting-edge industrial PC setups. These environments capitalize on connected devices for innovative solutions. Industrial PCs here enable machine learning, smart data analytics, and predictive maintenance. They connect seamlessly with IoT devices to create intelligent manufacturing systems. Security and seamless integration with existing technologies are paramount. Essential features for these PCs include:

- • Advanced processing power for machine learning

- • Seamless IoT integration for innovative processes

- • Strong security protocols to protect data integrity

By supporting cutting-edge technology, these industrial PC setups drive efficiency and innovation in smart factories.

Customization and Scalability in Industrial Computing Solutions

Customization plays a crucial role in tailoring industrial PCs to meet specific business needs. Each industry faces unique challenges and requires bespoke solutions for optimal performance. By offering customizable options, industrial PC vendors allow businesses to select features that matter most. These can include specialized I/O ports, enhanced processing power, and robust security systems. Scalability is equally important, ensuring that the computing solutions can grow alongside the business. Future-proof setups allow for adding new functionalities without overhauls.

Some customization and scalability features include:

- • Flexible hardware configurations

- • Options for additional memory and storage

- • Modular designs for easy upgrades

Investing in scalable and customizable solutions minimizes disruptions and helps align industrial PC systems with evolving operational demands. This approach ensures a seamless, long-term partnership between technology and the business's core functions.

Security and Reliability in Industrial PC Setups

Industrial PCs must offer robust security to shield operations from cyber threats. In industrial settings, a security breach can disrupt not just networks but entire production lines. To ensure reliability, industrial PCs are built to operate without interruptions. They withstand harsh conditions, including extreme temperatures and vibrations, ensuring consistent performance.

Key security and reliability features include:

- • Advanced encryption protocols

- • Ruggedized designs for tough environments

- • Regular firmware updates for threat protection

These features help safeguard sensitive data and maintain uninterrupted operations. With a reliable PC setup, industries avoid costly downtime and ensure long-term operational success.

Choosing the Right Industrial PC: Step-by-Step Guide

Selecting the right industrial PC is crucial for operational efficiency. Each industry has unique demands, so a tailored approach is essential. Begin by identifying specific requirements. Consider the environment where the PC will operate. Harsh conditions may require ruggedized solutions with advanced cooling systems. Next, evaluate processing power needs and connectivity options. Determine if the system must support multiple connections or high-speed data transfer.

Follow these steps for an informed choice:

- 1. Assess environmental conditions and durability requirements

- 2. Determine processing power and connectivity needs

- 3. Evaluate scalability and potential for future expansion

- 4. Consider security features to protect against cyber threats

Finally, factor in long-term benefits. Consider the total cost of ownership and potential downtime savings. A wise choice today can drive efficiency and lower costs in the long term.

Future Trends in Industrial Computing Solutions

The world of industrial computing evolves rapidly, with several key trends shaping the future. These innovations offer enhanced capabilities and greater efficiency. Firstly, the integration of artificial intelligence and machine learning is becoming more prevalent. Such technologies allow industrial PCs to analyze data swiftly and make informed decisions. Another trend is the growing use of edge computing. Processing data closer to the source reduces latency and improves response times.

Consider these emerging trends:

- • Enhanced AI and machine learning applications

- • Expansion of edge computing solutions

- • Increasing use of IoT devices for real-time data integration

Staying ahead of these trends can be vital. Embracing new technologies ensures your operations remain competitive and efficient. Adapting to these advancements can provide significant advantages in the industrial computing landscape.

Maximizing Value with the Right Industrial PC Setup

Choosing the right industrial PC setup is crucial for industry success. We hope this article has given you some helpful insight in what type of industrial computers you need. You can further explore our industrial computers here.

Whatever your application is and what environments you are in, if you need an industrial computing solution that is purpose-built for the harshest environments, InnoAioT has got you covered. If you don't know how to choose, please send us an email at info@innoaiot.com with your needs and our sales team will respond to you within 24 hours.