Stainless steel SUS304 ip69k waterproof panel PCs application in automatic filling beverage industry

In recent years, the beverage industry has developed rapidly, and the varieties of carbonated beverages, fruit juice beverages, vegetable juice beverages, milk-containing beverages, bottled drinking water, tea beverages, etc. have been continuously enriched. Juice beverage filling automation puts forward extremely high requirements on the adaptability and filling efficiency of containers of various specifications. Manufacturers in the food and beverage industry are constantly seeking to implement smart industry solutions to maximize profits by improving food quality and reducing production costs. However, the most important aspect of smart factory solutions for the food and beverage industry is its highly regulated industrial environment, which needs to maintain good sanitary conditions to ensure food safety, quality and productivity.

Equipment requirements

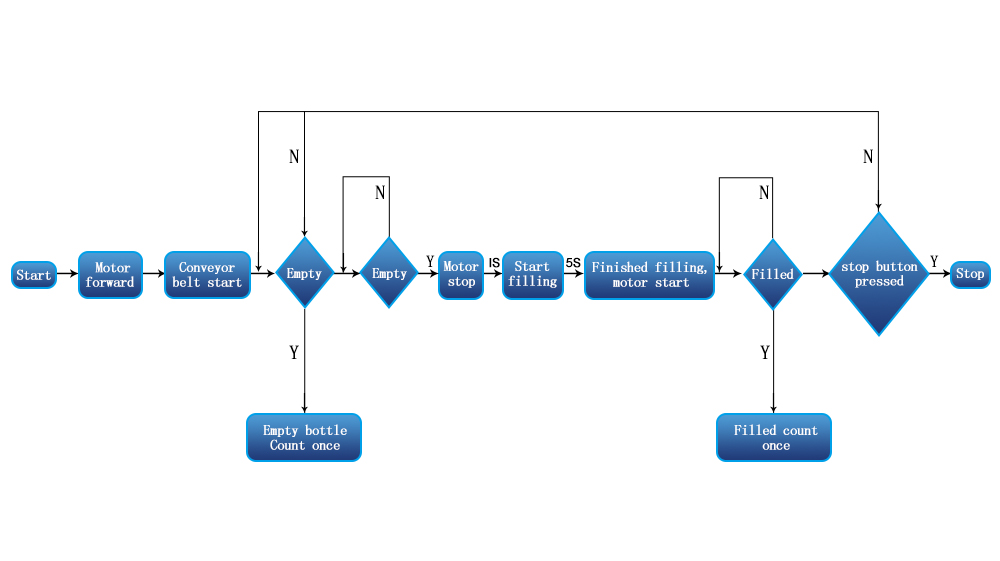

1. The system is set to automatic operation mode by the start button. then the drive motor of the production line conveyor starts and remains until the stop button is activated or the sensor under the filling equipment stops when an empty bottle is detected;

2. When the bottle is positioned under the filling equipment, delay 1 second, the filling equipment starts to work, and automatically stops 5 seconds later;

3. when the bottle is filled with beverages, the conveyor belt drive motor must be automatically started and kept until a new empty bottle is detected or the button is stopped.

Solutions and products

The WPC series waterproof touch Panel PC developed by InnoAioT with stainless steel SUS304 shell and IP66/IP69K waterproof rate. HMI solutions suitable for food and beverage manufacturing, meat/poultry processing, pharmaceutical processing, clean room manufacturing and outdoor placements, with anti-corrosion,waterproof and dust-proof functions to be used as host controllers. In order to facilitate daily cleaning and disinfection, lockable M12 I/O connectors ,to protect against vibration and shock,The M12 connector offer a reliable interface for high quality date acquisition or transmission.The Intel processor is ideal for use with software frequently used in the food and beverage industries such as ERP and MES software and other software used for live tracking of data, Eliminate the damage caused by washing equipment.the waterproof IP69K PCs are built for tough environments where wash-down or strong chemicals are used for cleaning.

Features

1. rigid,corrosive resistance stainless steel 304/316 enclose,IP66/IP69K waterproof rate

2. 15.6” TFT LED,1920X1080 screen resolution, 10-point capacitance touch

3. Intel Celeron J1900 2.0GHz processor ,silent ,fanless industrial tablet PC

4. 2*LAN support 1000m,2*COM RS232/422/485 interface,Whole PC Electro-Static discharge protection.Contact 6KV, non-contact: 8KV, surge: 600W

5. Impenetrable,locking M12 I/O connectors from water and debris,reach industrial IEC 61076-2-101 standard.